Flexible Circuit Material Cools Components On Curved Surfaces

Mahwah, NJ - MH&W International has introduced Keratherm 86/77 for providing electrically conductive bonding sites on a flexible, thermally conductive material that can be attached to non-linear, heat spreading structures. Uses include the mounting of LEDs and other hot components on curved surfaces where FR4, MCPCBs and other rigid materials can't be used. It also replaces thicker, heavier PCBs where size and weight are restricted, such as in portable electronics.

Mahwah, NJ - MH&W International has introduced Keratherm 86/77 for providing electrically conductive bonding sites on a flexible, thermally conductive material that can be attached to non-linear, heat spreading structures. Uses include the mounting of LEDs and other hot components on curved surfaces where FR4, MCPCBs and other rigid materials can't be used. It also replaces thicker, heavier PCBs where size and weight are restricted, such as in portable electronics.

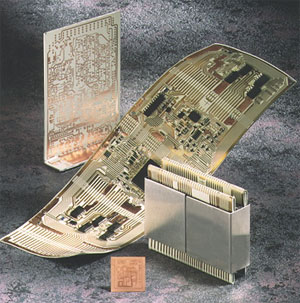

Keratherm 86/77 is a flexible thermal circuit, or FTC, that conists of a thin layer of etchable copper bonded to a highly thermally conductive silicone film. The strong, supple material can be applied to curved and irregular, heat spreading surfaces with peel-and-stick attachment. The material allows LED arrays to be placed along stairs and railings, inside headlights, across display cases, and other locations where LED usage requires both attachment and thermal management.

The new 86/77 copper and silicone material is produced with proven flex circuit manufacturing processes. Sheets, strips, and custom shapes are lighter and more flexible than both FR4 and MCPCBs (metal clad PC boards). The copper layer can be etched into a wide variety of circuit pathways.The conformable material ranges from 0.16 to 0.326 mm thick and can be secured with thermally conductive adhesive. Thermal transfer performance is superior to that of flexible circuits made from PI, PET and PEN films.

A single 86/77 flexible circuit can replace multiple boards, eliminating jumpers, connectors improving reliability. Different copper thicknesses are available for specific power requirements. With the copper layer intact, the material can also be formed into a Faraday-cage design for EMI protection. Unlike some other PC board materials, Kertherm 86/77 contains no hazardous materials, such as flame retardants. Parts can be readily handled, fabricated and recycled.

SOURCE: MH&W International